How does the vanDrawee system differ from conventional systems?

Ubiquitous clamping grooves, i.e. throughout the entire structure on all sides of all profiles

After the vehicle is out of service, all profiles can be used for a shelf in another type of vehicle or any other product in the company.

You can quickly take whole sets of tools and materials in boxes outside the vehicle (conventional drawers do not allow this).

The extendable aluminium frames with locking can be fitted with plastic euro-brackets 400x300, 600x400 mm of different heights.

The rack structure can be extended at any point in any direction, with another rack, a part of it or just the profile itself as required.

The user of the vanDrawee system is not dependent on the original accessories; thanks to the ubiquitous grooves, the rack can be fitted with its own elements.

We are not limited by dimensional ranges, we can produce a completely individual fitting for any vehicle type N1. We will adapt the dimensions to the millimetre to your needs.

Easy parts recovery, any damaged part can be replaced for a fraction of the price compared to conventional car systems, because e.g. the shelf is not made of one piece of material, but contains multiple parts

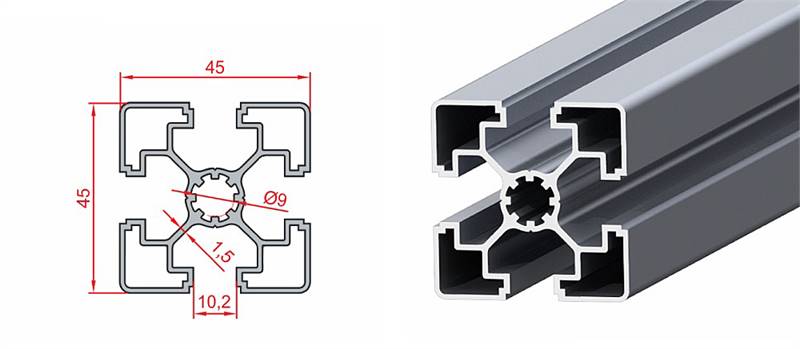

The main structure consists of a 45x45mm aluminium profile

Naturally anodized.

All extensions have 100% extension.

Each extension has a load capacity of 50kg, anti-extrusion locking.

High variability of the system with the possibility of many accessories.

The bottom of the shelves is always made of 10mm foiled poplar plywood, the fronts are made of durable 10mm thick plastic with a tread,

shelf sides of your choice: poplar plywood, 10mm plastic, or aluminium slats (the design solution with the lowest resistance)